Kev Tshawb Fawb Txog Kev Nce Qib ntawm Cov Polyurethanes Uas Tsis Yog Isocyanate

Txij li thaum lawv tau qhia tawm xyoo 1937, cov ntaub ntawv polyurethane (PU) tau pom ntau daim ntawv thov thoob plaws ntau yam kev lag luam suav nrog kev thauj mus los, kev tsim kho, petrochemicals, textiles, mechanical thiab electrical engineering, aerospace, kev kho mob, thiab kev ua liaj ua teb. Cov ntaub ntawv no yog siv rau hauv cov ntaub ntawv xws li cov yas ua npuas ncauj, fibers, elastomers, cov neeg sawv cev tiv thaiv dej, tawv hluavtaws, coatings, adhesives, paving cov ntaub ntawv thiab cov khoom siv kho mob. PU ib txwm muaj feem ntau yog synthesized los ntawm ob lossis ntau dua isocyanates nrog rau macromolecular polyols thiab me me molecular saw extenders. Txawm li cas los xij, qhov tshuaj lom ntawm isocyanates ua rau muaj kev pheej hmoo loj rau tib neeg kev noj qab haus huv thiab ib puag ncig; ntxiv rau lawv feem ntau yog los ntawm phosgene - ib qho tshuaj lom heev - thiab cov ntaub ntawv amine raw.

Vim yog kev lag luam tshuaj lom neeg niaj hnub no nrhiav kev txhim kho ntsuab thiab ruaj khov, cov kws tshawb fawb tau tsom mus rau kev hloov cov isocyanates nrog cov khoom siv uas tsis ua rau ib puag ncig puas tsuaj thaum tshawb nrhiav cov kev tsim cov polyurethanes uas tsis yog isocyanate (NIPU). Tsab ntawv no qhia txog cov kev npaj rau NIPU thaum tshuaj xyuas kev nce qib hauv ntau hom NIPUs thiab tham txog lawv cov kev cia siab yav tom ntej los muab cov ntaub ntawv siv rau kev tshawb fawb ntxiv.

1 Kev Tsim Cov Polyurethanes Uas Tsis Yog Isocyanate

Thawj qhov kev tsim cov tshuaj carbamate uas tsis muaj molecular hnyav siv monocyclic carbonates ua ke nrog aliphatic diamines tau tshwm sim txawv teb chaws hauv xyoo 1950s - cim lub sijhawm tseem ceeb rau kev tsim cov polyurethane uas tsis yog isocyanate. Tam sim no muaj ob txoj hauv kev tseem ceeb rau kev tsim NIPU: Thawj qhov cuam tshuam nrog cov tshuaj ntxiv ntawm binary cyclic carbonates thiab binary amines; qhov thib ob cuam tshuam nrog cov tshuaj polycondensation uas muaj diurethane intermediates nrog rau diols uas pab txhawb kev sib pauv hauv carbamates. Diamarboxylate intermediates tuaj yeem tau txais los ntawm cyclic carbonate lossis dimethyl carbonate (DMC) txoj kev; feem ntau txhua txoj hauv kev cuam tshuam los ntawm cov pab pawg carbonic acid uas ua rau muaj kev ua haujlwm ntawm carbamate.

Cov ntu hauv qab no piav qhia txog peb txoj hauv kev sib txawv los tsim cov polyurethane yam tsis siv isocyanate.

1.1 Txoj Kev Binary Cyclic Carbonate

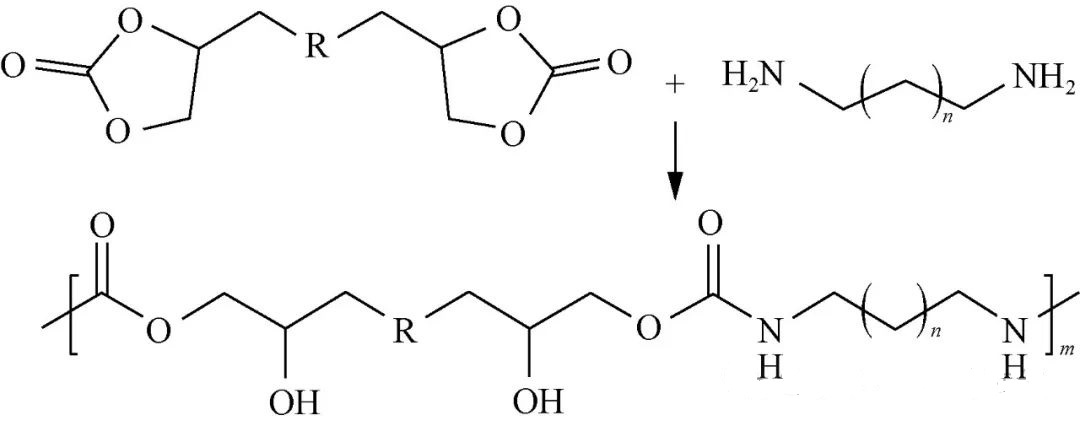

NIPU tuaj yeem tsim tau los ntawm kev ntxiv cov kauj ruam uas muaj binary cyclic carbonate ua ke nrog binary amine raws li tau qhia hauv Daim Duab 1.

Vim muaj ntau pawg hydroxyl nyob hauv cov chav rov ua dua raws li nws cov qauv tseem ceeb, txoj kev no feem ntau ua rau muaj qhov hu ua polyβ-hydroxyl polyurethane (PHU). Leitsch et al., tau tsim ntau cov polyether PHUs siv cov polyethers cyclic carbonate-terminated nrog rau cov binary amines ntxiv rau cov molecule me me uas tau los ntawm cov binary cyclic carbonates - piv rau cov txheej txheem ib txwm siv rau kev npaj polyether PUs. Lawv cov kev tshawb pom qhia tau hais tias cov pab pawg hydroxyl hauv PHUs yooj yim tsim cov hydrogen bonds nrog cov nitrogen/oxygen atoms nyob hauv cov ntu mos/nyuaj; kev hloov pauv ntawm cov ntu mos kuj cuam tshuam rau tus cwj pwm hydrogen bonding nrog rau cov qib sib cais microphase uas tom qab ntawd cuam tshuam rau tag nrho cov yam ntxwv kev ua tau zoo.

Feem ntau ua rau qhov kub qis dua 100 ° C txoj kev no tsis tsim cov khoom seem thaum lub sijhawm ua tshuaj tiv thaiv ua rau nws tsis tshua muaj zog rau cov dej noo thaum tsim cov khoom ruaj khov tsis muaj kev txhawj xeeb txog kev hloov pauv tab sis xav tau cov kuab tshuaj organic uas muaj lub zog polarity xws li dimethyl sulfoxide (DMSO), N, N-dimethylformamide (DMF), thiab lwm yam. Tsis tas li ntawd, lub sijhawm ua tshuaj tiv thaiv ntev dua li ib hnub txog tsib hnub feem ntau ua rau cov phaus molecular qis dua feem ntau poob qis dua qhov txwv nyob ib puag ncig 30k g / mol ua rau kev tsim khoom loj nyuaj vim feem ntau yog vim ob qho tib si tus nqi siab cuam tshuam nrog rau qhov ntawd ua rau lub zog tsis txaus los ntawm cov PHUs tshwm sim txawm tias muaj kev siv zoo uas nthuav dav cov khoom siv damping, duab, cim xeeb, tsim, nplaum, txheej, daws, ua npuas dej, thiab lwm yam.

1.2 Txoj Kev Monocylic Carbonate

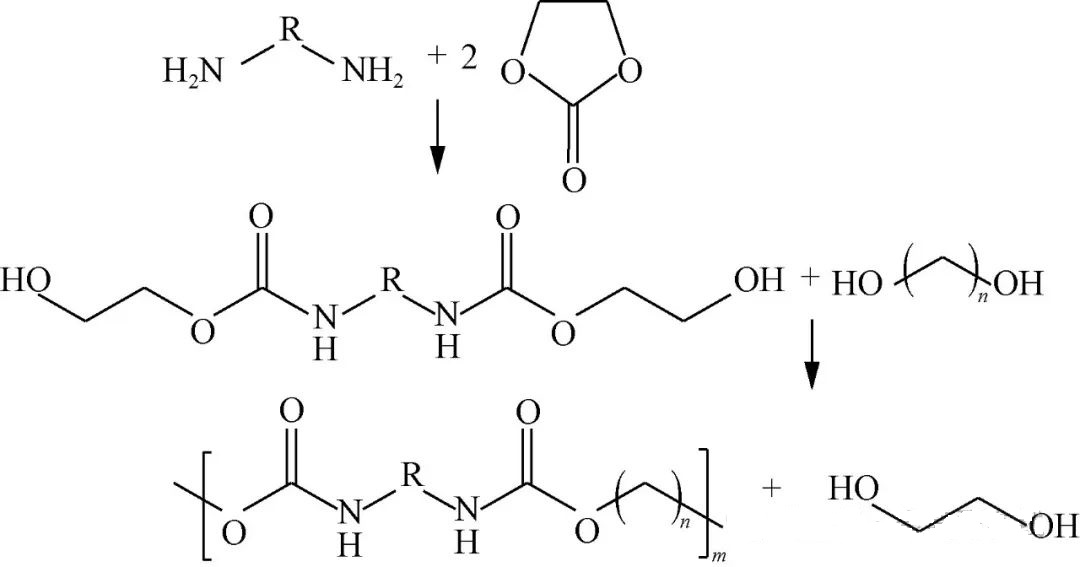

Monocylic carbonate teb ncaj qha nrog diamine ua rau dicarbamate muaj cov pab pawg kawg hydroxyl uas tom qab ntawd dhau los ua kev sib cuam tshuam tshwj xeeb transesterification / polycondensation nrog rau diols thaum kawg tsim cov NIPU structurally akin cov counterparts ib txwm muaj duab pom ntawm Daim Duab 2.

Cov monocylic variants feem ntau siv suav nrog ethylene & propylene carbonated substrates qhov twg Zhao Jingbo pab pawg ntawm Beijing University Of Chemical Technology tau koom nrog ntau yam diamines teb lawv tawm tsam cov cyclical entities thawj zaug tau txais ntau yam structural dicarbamate intermediaries ua ntej mus rau cov theem condensation siv polytetrahydrofuranediol / polyether-diols culminating kev tsim cov kab khoom zoo uas qhia txog cov khoom thermal / mechanical zoo kawg nkaus ncav cuag cov ntsiab lus melting hovering nyob ib puag ncig ntau yam txuas ntxiv kwv yees li 125 ~ 161 ° C tensile zog peaking ze li 24MPa elongation nqi ze li 1476%. Wang et al., cov kev sib xyaw ua ke zoo sib xws suav nrog DMC ua ke nrog / hexamethylenediamine / cyclocarbonated precursors synthesizing hydroxy-terminated derivatives tom qab ntawd raug biobased dibasic acids xws li oxalic / sebacic / acids adipic-acid-terephtalics ua tiav cov zis kawg qhia txog ntau yam suav nrog 13k ~ 28k g / mol tensile zog fluctuating 9 ~ 17 MPa elongations sib txawv 35% ~ 235%.

Cov cyclocarbonic esters koom tes zoo yam tsis tas yuav tsum muaj cov catalysts nyob rau hauv cov xwm txheej ib txwm muaj uas tswj tau qhov kub thiab txias li ntawm 80 ° txog 120 ° C tom qab ntawd transesterifications feem ntau siv cov txheej txheem catalytic raws li organotin kom ntseeg tau tias qhov ua tiav zoo tshaj plaws tsis tshaj 200 °. Tshaj li kev siv zog condensation tsom mus rau diolic inputs muaj peev xwm ua rau tus kheej-polymerization / deglycolysis phenomena pab txhawb kev tsim cov txiaj ntsig xav tau ua rau cov txheej txheem inherently eco-friendly feem ntau yielding methanol / me me-molecule-diolic residues yog li nthuav tawm cov kev xaiv kev lag luam muaj peev xwm mus tom ntej.

1.3 Txoj Kev Dimethyl Carbonate

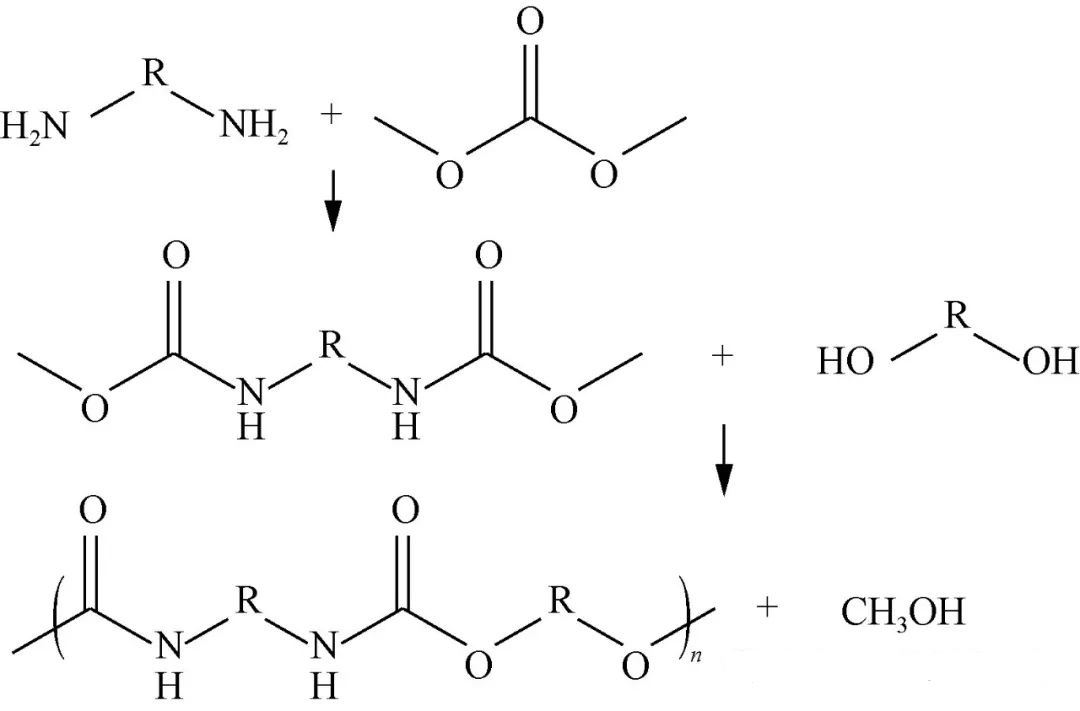

DMC sawv cev rau lwm txoj hauv kev uas zoo rau ib puag ncig/tsis muaj tshuaj lom uas muaj ntau yam khoom siv ua haujlwm suav nrog methyl/methoxy/carbonyl configurations txhim kho cov qauv reactivity uas ua rau muaj kev sib koom tes thawj zaug uas DMC cuam tshuam ncaj qha nrog/diamines tsim cov methyl-carbamate me me uas raug tshem tawm ua ntej thiab tom qab ntawd ua rau cov txheej txheem yaj-condensing suav nrog cov khoom me me-chain-extender-diolics/loj dua-polyol ua rau muaj cov qauv polymer uas xav tau tom qab pom raws li daim duab 3.

Deepa et.al tau siv cov dynamics uas tau hais los saum toj no los siv sodium methoxide catalysis los tsim ntau hom intermediate formations, tom qab ntawd koom nrog cov extensions uas tau tsom mus rau qhov sib npaug ntawm cov khoom sib xyaw ua ke uas ua tiav qhov hnyav molecular kwv yees li (3 ~ 20) x 10 ^ 3g / mol iav hloov pauv kub (-30 ~ 120 ° C). Pan Dongdong tau xaiv cov khub sib txuas ua ke uas muaj DMC hexamethylene-diaminopolycarbonate-polyalcohols uas ua tiav cov txiaj ntsig zoo tshaj plaws uas qhia txog cov ntsuas tensile-strength oscillating 10-15MPa elongation ratios ze li ntawm 1000% -1400%. Kev tshawb nrhiav txog cov kev cuam tshuam sib txawv ntawm cov saw hlau tau qhia txog kev nyiam sib phim cov kev xaiv butanediol / hexanediol thaum atomic-number parity tswj kev sib npaug txhawb kev txhim kho crystallinity pom thoob plaws cov saw hlau. Sarazin pawg tau npaj cov khoom sib xyaw ua ke lignin / DMC nrog rau hexahydroxyamine qhia txog cov yam ntxwv zoo ntawm cov khoom siv tom qab ua tiav ntawm 230 ℃. Kev tshawb nrhiav ntxiv tsom mus rau kev nrhiav cov khoom tsis yog isocyante-polyureas siv diazomonomer kev koom tes uas xav tau cov ntawv thov xim uas muaj txiaj ntsig zoo dua li cov vinyl-carbonaceous counterparts qhia txog kev siv nyiaj / kev nrhiav ntau dua. Kev saib xyuas zoo txog cov txheej txheem synthesized feem ntau xav tau qhov kub siab / chaw nqus tsev tsis lees paub cov kev xav tau cov kuab tshuaj yog li txo cov dej khib nyiab feem ntau txwv tsuas yog methanol / me me-molecule-diolic effluents tsim cov qauv synthesized ntsuab dua.

2 Cov ntu mos sib txawv ntawm cov polyurethane uas tsis yog isocyanate

2.1 Polyether polyurethane

Polyether polyurethane (PEU) yog siv dav vim nws lub zog sib txuas tsawg ntawm ether bonds hauv cov khoom siv rov ua dua, yooj yim tig, yooj yim hloov pauv kub qis thiab tsis kam hydrolysis.

Kebir et al. tau tsim cov polyether polyurethane nrog DMC, polyethylene glycol thiab butanediol ua cov khoom siv raw, tab sis qhov hnyav molecular qis (7 500 ~ 14 800g / mol), Tg qis dua 0 ℃, thiab qhov melting point kuj qis (38 ~ 48 ℃), thiab lub zog thiab lwm yam ntsuas nyuaj rau ua kom tau raws li qhov xav tau ntawm kev siv. Zhao Jingbo pawg tshawb fawb siv ethylene carbonate, 1, 6-hexanediamine thiab polyethylene glycol los tsim cov PEU, uas muaj qhov hnyav molecular ntawm 31 000g / mol, lub zog tensile ntawm 5 ~ 24MPa, thiab elongation ntawm tawg ntawm 0.9% ~ 1 388%. Qhov hnyav molecular ntawm cov tshuaj synthesized ntawm aromatic polyurethanes yog 17 300 ~ 21 000g / mol, Tg yog -19 ~ 10 ℃, qhov chaw yaj yog 102 ~ 110 ℃, lub zog tensile yog 12 ~ 38MPa, thiab qhov rov qab elastic ntawm 200% tas li elongation yog 69% ~ 89%.

Pawg tshawb fawb ntawm Zheng Liuchun thiab Li Chuncheng tau npaj cov khoom nruab nrab 1, 6-hexamethylenediamine (BHC) nrog dimethyl carbonate thiab 1, 6-hexamethylenediamine, thiab polycondensation nrog cov molecules me me sib txawv ncaj saw diols thiab polytetrahydrofuranediols (Mn = 2 000). Ib qho series ntawm polyether polyurethanes (NIPEU) nrog txoj kev tsis yog isocyanate tau npaj, thiab qhov teeb meem crosslinking ntawm cov khoom nruab nrab thaum lub sijhawm tshuaj tiv thaiv tau daws. Cov qauv thiab cov khoom ntawm cov tshuaj polyether polyurethane ib txwm muaj (HDIPU) uas NIPEU npaj thiab 1, 6-hexamethylene diisocyanate tau muab piv, raws li qhia hauv Rooj 1.

| Qauv | Feem pua ntawm cov khoom nyuaj /% | Qhov hnyav molecular / (g·mol^(-1)) | Cov ntsuas qhov hnyav ntawm cov molecular | Lub zog tensile / MPa | Kev ntev thaum tawg /% |

| NIPEU30 | 30 | 74000 | 1.9 | 12.5 | 1250 |

| NIPEU40 | 40 | 66000 | 2.2 | 8.0 | 550 |

| HDIPU30 | 30 | 46000 | 1.9 | 31.3 | 1440 |

| HDIPU40 | 40 | 54000 | 2.0 | 25.8 | 1360 xyoo |

Rooj 1

Cov txiaj ntsig hauv Rooj 1 qhia tau hais tias qhov sib txawv ntawm cov qauv ntawm NIPEU thiab HDIPU feem ntau yog vim yog qhov nyuaj. Pawg urea uas tsim los ntawm kev cuam tshuam sab ntawm NIPEU raug muab tso rau hauv cov saw hlau molecular ntawm qhov nyuaj, rhuav tshem qhov nyuaj kom tsim cov hydrogen bonds, ua rau cov hydrogen bonds tsis muaj zog ntawm cov saw hlau molecular ntawm qhov nyuaj thiab crystallinity qis ntawm qhov nyuaj, ua rau muaj kev sib cais theem qis ntawm NIPEU. Yog li ntawd, nws cov khoom siv kho tshuab tsis zoo dua li HDIPU.

2.2 Polyester Polyurethane

Polyester polyurethane (PETU) nrog polyester diols ua cov ntu mos mos muaj kev puas tsuaj zoo, biocompatibility thiab cov khoom siv kho tshuab, thiab tuaj yeem siv los npaj cov ntaub so ntswg engineering scaffolds, uas yog cov khoom siv biomedical nrog kev cia siab zoo. Polyester diols feem ntau siv rau hauv cov ntu mos mos yog polybutylene adipate diol, polyglycol adipate diol thiab polycaprolactone diol.

Ua ntej, Rokicki et al. tau ua rau ethylene carbonate nrog diamine thiab diols sib txawv (1, 6-hexanediol,1, 10-n-dodecanol) kom tau txais NIPU sib txawv, tab sis NIPU uas tau tsim muaj qhov hnyav molecular qis dua thiab Tg qis dua. Farhadian et al. tau npaj polycyclic carbonate siv roj noob paj noob hlis ua cov khoom siv raw, tom qab ntawd sib xyaw nrog bio-based polyamines, coated rau ntawm lub phaj, thiab kho ntawm 90 ℃ rau 24 teev kom tau txais thermosetting polyester polyurethane zaj duab xis, uas qhia tau tias muaj kev ruaj khov thermal zoo. Pawg tshawb fawb ntawm Zhang Liqun los ntawm South China University of Technology tau tsim cov diamines thiab cyclic carbonates, thiab tom qab ntawd condensed nrog biobased dibasic acid kom tau txais biobased polyester polyurethane. Zhu Jin pawg tshawb fawb ntawm Ningbo Institute of Materials Research, Chinese Academy of Sciences tau npaj diaminodiol hard segment siv hexadiamine thiab vinyl carbonate, thiab tom qab ntawd polycondensation nrog bio-based unsaturated dibasic acid kom tau txais cov polyester polyurethane, uas tuaj yeem siv ua xim tom qab ultraviolet curing [23]. Pawg tshawb fawb ntawm Zheng Liuchun thiab Li Chuncheng siv adipic acid thiab plaub aliphatic diols (butanediol, hexadiol, octanediol thiab decanediol) nrog cov lej carbon atomic sib txawv los npaj cov polyester diols sib xws ua cov ntu mos; Ib pawg ntawm cov tsis yog isocyanate polyester polyurethane (PETU), hu ua tom qab tus lej ntawm cov carbon atoms ntawm aliphatic diols, tau txais los ntawm kev yaj polycondensation nrog hydroxy-sealed hard segment prepolymer npaj los ntawm BHC thiab diols. Cov khoom siv kho tshuab ntawm PETU tau qhia hauv Rooj 2.

| Qauv | Lub zog tensile / MPa | Cov qauv elastic/MPa | Kev ntev thaum tawg /% |

| PETU4 | 6.9±1.0 | 36±8 | 673±35 |

| PETU6 | 10.1±1.0 | 55±4 | 568±32 |

| PETU8 | 9.0±0.8 | 47±4 | 551±25 |

| PETU10 | 8.8±0.1 | 52±5 | 137±23 |

Rooj 2

Cov txiaj ntsig qhia tau hais tias qhov mos mos ntawm PETU4 muaj qhov ceev carbonyl siab tshaj plaws, qhov sib txuas hydrogen muaj zog tshaj plaws nrog qhov nyuaj, thiab qib sib cais theem qis tshaj plaws. Kev siv lead ua ntawm ob qho tib si mos mos thiab tawv yog txwv, qhia qhov melting point qis thiab tensile zog, tab sis qhov siab tshaj plaws elongation ntawm tawg.

2.3 Polycarbonate polyurethane

Polycarbonate polyurethane (PCU), tshwj xeeb tshaj yog aliphatic PCU, muaj kev tiv thaiv hydrolysis zoo heev, tiv thaiv oxidation, ruaj khov zoo thiab biocompatibility, thiab muaj kev cia siab zoo hauv kev siv biomedicine. Tam sim no, feem ntau ntawm NIPU npaj siv polyether polyols thiab polyester polyols ua cov ntu mos, thiab muaj ob peb daim ntawv tshawb fawb txog polycarbonate polyurethane.

Cov polycarbonate polyurethane uas tsis yog isocyanate uas tau npaj los ntawm Tian Hengshui pawg tshawb fawb ntawm South China University of Technology muaj qhov hnyav molecular ntau dua 50 000 g / mol. Kev cuam tshuam ntawm cov xwm txheej tshuaj tiv thaiv rau qhov hnyav molecular ntawm cov polymer tau raug kawm, tab sis nws cov khoom siv kho tshuab tsis tau tshaj tawm. Zheng Liuchun thiab Li Chuncheng pawg tshawb fawb tau npaj PCU siv DMC, hexanediamine, hexadiol thiab polycarbonate diols, thiab hu ua PCU raws li qhov feem pua ntawm qhov nyuaj ntawm qhov rov ua dua. Cov khoom siv kho tshuab tau qhia hauv Rooj 3.

| Qauv | Lub zog tensile / MPa | Cov qauv elastic/MPa | Kev ntev thaum tawg /% |

| PCU18 | 17±1 | 36±8 | 665±24 |

| PCU33 | 19±1 | 107±9 | 656±33 |

| PCU46 | 21±1 | 150±16 | 407±23 |

| PCU57 | 22±2 | 210±17 | 262±27 |

| PCU67 | 27±2 | 400±13 | 63±5 |

| PCU82 | 29±1 | 518±34 | 26±5 |

Rooj 3

Cov txiaj ntsig qhia tau tias PCU muaj qhov hnyav molecular siab, txog li 6 × 104 ~ 9 × 104g / mol, melting point txog li 137 ℃, thiab tensile zog txog li 29 MPa. Hom PCU no tuaj yeem siv ua cov yas ruaj khov lossis ua elastomer, uas muaj kev cia siab zoo hauv kev siv biomedical (xws li cov ntaub so ntswg tib neeg lossis cov ntaub ntawv cog rau lub plawv).

2.4 Cov polyurethane sib xyaw uas tsis yog isocyanate

Hybrid non-isocyanate polyurethane (hybrid NIPU) yog kev qhia txog epoxy resin, acrylate, silica lossis siloxane pawg rau hauv polyurethane molecular framework los tsim ib lub network interpenetrating, txhim kho kev ua tau zoo ntawm polyurethane lossis muab cov polyurethane ua haujlwm sib txawv.

Feng Yuelan thiab lwm tus tau sib xyaw cov roj taum pauv epoxy bio-based nrog CO2 los ua cov pentamonic cyclic carbonate (CSBO), thiab tau qhia txog bisphenol A diglycidyl ether (epoxy resin E51) nrog cov saw hlau uas tawv dua los txhim kho NIPU uas tsim los ntawm CSBO uas khov nrog amine. Cov saw hlau molecular muaj cov saw hlau ntev uas yoog tau ntawm oleic acid/linoleic acid. Nws kuj muaj cov saw hlau uas tawv dua, yog li nws muaj lub zog siab thiab tawv heev. Qee tus kws tshawb fawb kuj tau sib xyaw peb hom NIPU prepolymers nrog furan kawg pawg los ntawm kev sib xyaw ntawm diethylene glycol bicyclic carbonate thiab diamine, thiab tom qab ntawd sib xyaw nrog unsaturated polyester los npaj cov polyurethane mos uas muaj kev kho tus kheej, thiab tau ua tiav qhov kev kho tus kheej zoo ntawm NIPU mos. Hybrid NIPU tsis yog tsuas yog muaj cov yam ntxwv ntawm NIPU dav dav xwb, tab sis kuj tseem yuav muaj kev sib txuas zoo dua, tiv taus acid thiab alkali corrosion, tiv taus cov kuab tshuaj thiab lub zog kho tshuab.

3 Lub Zeem Muag

NIPU yog npaj tsis siv cov tshuaj lom isocyanate, thiab tam sim no tab tom kawm ua cov ua npuas ncauj, txheej, nplaum, elastomer thiab lwm yam khoom, thiab muaj ntau yam kev siv. Txawm li cas los xij, feem ntau ntawm lawv tseem txwv rau kev tshawb fawb hauv chaw kuaj mob, thiab tsis muaj kev tsim khoom loj. Tsis tas li ntawd, nrog kev txhim kho ntawm cov neeg lub neej thiab kev loj hlob ntawm kev thov, NIPU nrog ib qho kev ua haujlwm lossis ntau yam kev ua haujlwm tau dhau los ua qhov kev tshawb fawb tseem ceeb, xws li kev tua kab mob, kev kho tus kheej, kev nco qab zoo li cas, hluav taws kub retardant, kev tiv taus kub siab thiab lwm yam. Yog li ntawd, kev tshawb fawb yav tom ntej yuav tsum nkag siab yuav ua li cas tawg los ntawm cov teeb meem tseem ceeb ntawm kev lag luam thiab txuas ntxiv tshawb nrhiav kev taw qhia ntawm kev npaj NIPU ua haujlwm.

Lub sijhawm tshaj tawm: Lub Yim Hli-29-2024